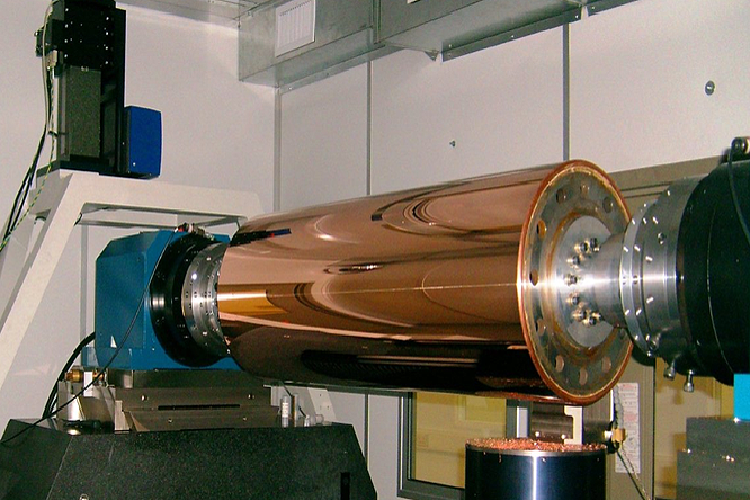

Hydrostatic Spindle Technology

overview

When also microns count (0.001 mm)

TDM SA has developed a wide range of hydrostatic motor spindles.

They are used mainly in high precision applications and mostly in high

precision machine tools.

The major properties of this system are:

- No wear ( life time is virtually unlimited)

- No friction at low velocity and no stick-slip , so maximum precision positioning is available

- Thermal stability, heat removal directly through lubricating oil

- Ultra-high rotational accuracy

- Extremely high damping coefficient

- Low thermal expansion

- This new generation of spindles developed by TDM SA allows extremely high speeds up to 250'000 rpm

SPINDLES ADVANTAGES FOR PRECISION GRINDING APPLICATIONS

Hydrostatic Spindles are only one type of spindles that effectively combine ultra-high rotational accuracy with ultra-high vibration resistance, high static stiffness and virtually infinite life.

This unique combination provides a number of very essential advantages in precision grinding applications.

TDM SA hydrostatic work head grinding spindle have a rotational

speed up to 12,000 RPM with rotational accuracy in radial

direction within 20 nanometers and can be improved to 10

nanometers to meet special customer requirements.

TDM SA hydrostatic internal grinding spindles can run up to

speed 250,000 RPM with rotational accuracy in radial direction

between 30 nanometers and 90 nanometers in dependence of speed.

The unique spindles design based on more than 3 decades experience with computerized parameters optimization and with Final Elements Analysis of shaft dynamics, stability and resonance, is exhibits high stiffness and extremely high reliability with minimal friction losses.

-

Geometrical Accuracy.

Roundness of the ground part is mainly defined by synchronous error motion of the work head spindle for both internal and external grinding applications.

-

Surface Roughness.

In contrast to geometrical accuracy, the main influence on surface roughness is due to asynchronous error motion of the grinding spindle (for OD grinding as well as for ID grinding). Parts with extremely high surface quality are obtained with hydrostatic grinding spindles because of their accuracy, repeatability, smooth, and vibration free rotation. For hardened steel parts surface roughness better than 8 nanometers Ra can be reached in relatively short time (depending on the size of ground part). In grinding of optics components using TDM SA hydrostatic spindles, the surface roughness with Ra about 1 nanometer has been achieved.

-

Productivity.

Hydrostatic spindles are very effectively used not only for extremely high precision application, but for standard requirements with significantly increased productivity.

High stiffness and high vibration resistance permit much higher chatter free grinding forces.

Grinding process by its nature is an averaging process. Spark-out portion of the grinding cycle improves surface quality without to change the actual size.

Because of ultra-high rotational accuracy as well as extremely high rotational repeatability the averaging process is much quicker and as a result, the spark-out time can be reduced significantly.

-

Grinding using CBN wheels.

The quality of parts ground with CBN wheels is especially sensitive to accuracy and vibration free performance of the grinding spindle as well as accuracy and stability of the work head spindle. This makes hydrostatic spindles undoubtedly the optimal choice for every precision grinding application using CBN wheels.