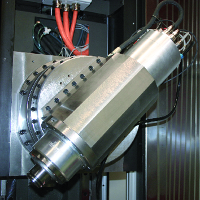

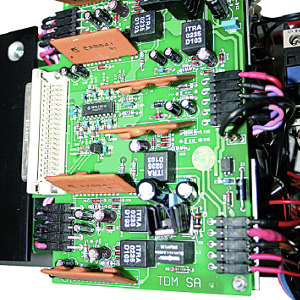

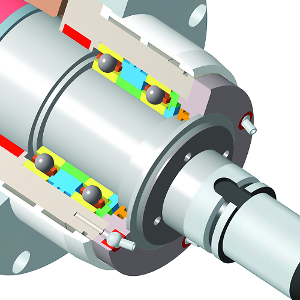

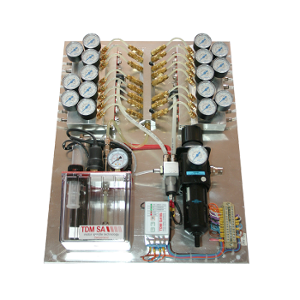

TDM Products

20 years of experience in development and manufacturing spindles and asynchronous /synchronous

motors

as well as close relationships with well-known machine tool manufacturers gave us an

opportunity to create a wide range of innovative high technology products to satisfy the

highest requirements from our customers. Today, TDM can offer solutions for any type of

machining such as grinding, milling and turning