Milling ...and light milling

Details

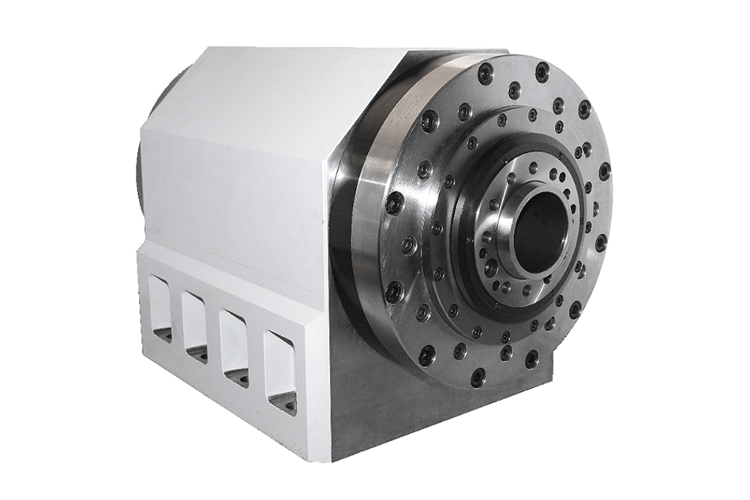

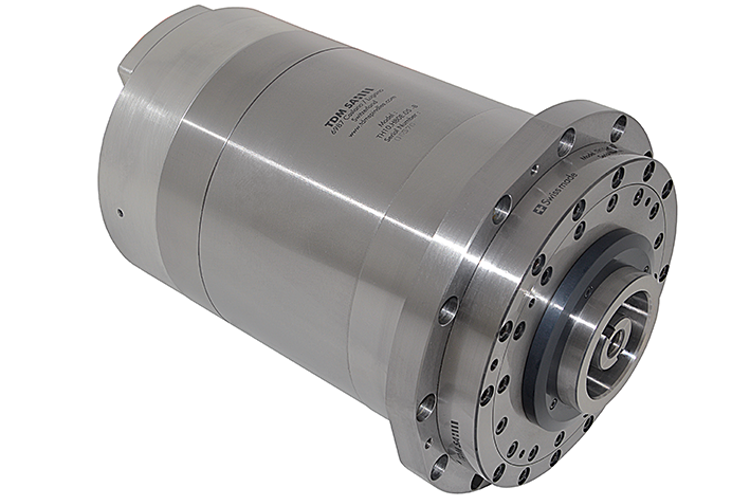

Motor spindles for milling

These spindles were designed to be used on machine tools for the production of components for the aeronautical and automotive industries. These motor spindles combine high rigidity and high rotational speed. The design of TDM spindles are always based on the same concept from spindle to spindle. Spindles are tested to meet the high technological requirements in optimal way.

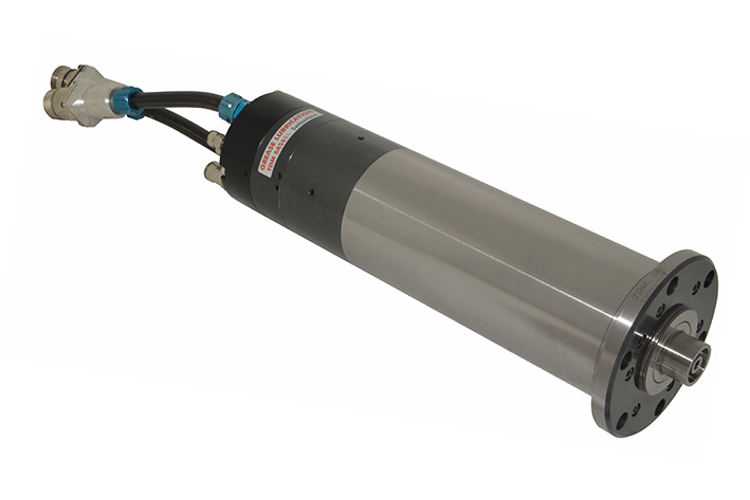

Motor spindles for light milling

Conceived to be used on machine tools for the watch industry components manufacturing, spindles for light milling effectively combine high rigidity and compact design. Apart from working with very close tolerances, these spindles can be mounted next to another with a significantly reduced space between the spindles axes (up to 55mm). Despite the compact design, sensors can be mounted to check various parameters such as vibration, shock, thermal expansion, bearing temperature and encoders. TDM SA can offer to its clients a wide range of spindles for light milling.

Specs

- Power: Up to 100 kW

- Moment: Up to 1200 Nm (S1)

- Tool holder: HSK, ISO, Capto and others

- Bearing lubrication: Permanent grease or air-oil lubrication

- Spindle diameter: Up to 400 mm

- Motors: Synchronous and asynchronous

- Bearings: Hybrid bearings, steel and ceramic

Download catalogue (de)